One of my favorite fall chores is to take a box of our beautiful Mendocino Gravenstein apples and turn them into jars of applesauce. The Gravenstein is not a good keeping apple, and loses its crisp texture and incredible balance of sweet and tart flavors within a week or so of picking, even when stored under the best conditions. We get these apples here for about 4-6 weeks in mid August through late September, and while we eat as many as we can practically consume in that time period, I find myself craving the flavor in the darker months of winter when the only fruit on the store shelves are citrus and jet-setting bananas.

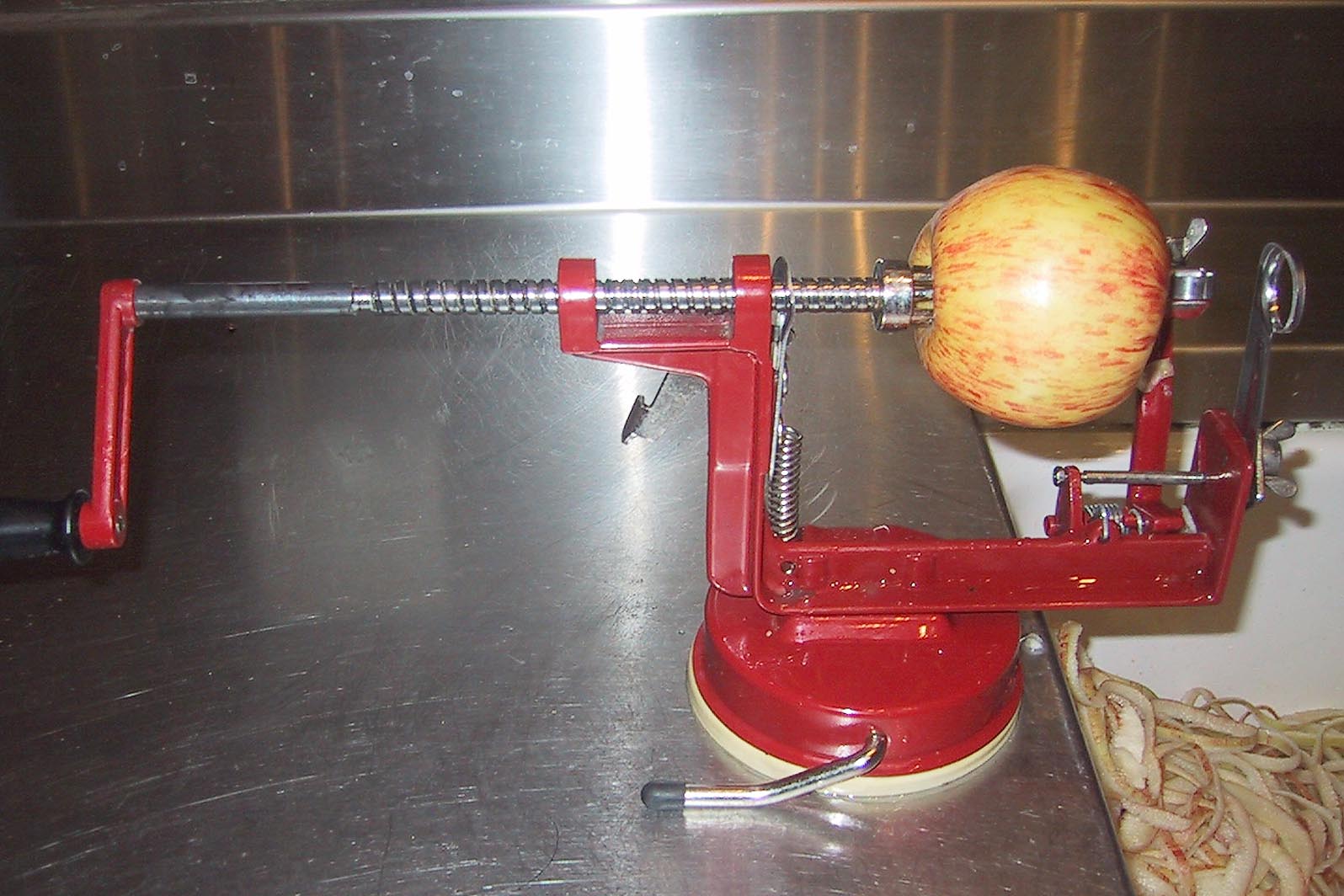

One of the fun parts of making applesauce, aside from the tasting, of course, is using the apple peeling machine. This device resembles one of the pieces from the children’s game “Mousetrap,” and appears virtually unchanged from its original version, with the exception of the suction mechanism that allows me to mount it on the stainless steel countertop next to the sink. After setting the various blades and springs, an apple is speared, through the stem end, on the prongs. Turning the crank rotates the apple against the peeling blade while pushing the entire fruit through the coring and cutting blades. At the end of the process, you are left with spiral sliced fruit, a neat core containing stem and seeds, and yards of thin peels resembling a Halloween wig.

After processing the entire box, the large kettle is full of the sliced apples, and I add several cups of water, some lemon juice to balance the sweetness, and whole nutmegs and stick cinnamon for flavor. The kettle is set over medium heat and stirred frequently to keep the fruit from sticking. The process of reducing the fruit to sauce consistency takes several hours, and the entire kitchen begins to smell reminiscent of apple pie. The only downside is that the open kettle occasionally spits small pieces of fruit in all directions, coating the backsplash and stovetop with sticky bits.

When the fruit is cooked down, the entire mash is run through the same mill I use for making tomato sauce, removing any remaining skin, seeds or fibrous pulp. The smooth puree is transferred into the smaller kettle, and the rest is added to the cores and skins in the compost bin. The sauce is reheated to reduce and thicken, and tasted for last minute additions of either sugar or lemon. With Gravenstein apples, this is rarely needed, as they seem to have been bred to make the perfect applesauce.

The canning process is routine by this time; the same steps using in canning the tomato sauce. Care must be taken not to drip the lava-like sauce onto arms or hands while filling the hot jars. A Chinese chef once taught me to coat my hands and forearms with cooking oil before stir-frying in a hot wok; the theory being that the oil would prevent food splashes from sticking to the skin and causing serious burns. I have found that this is also very effective with canning fruit products, and leaves my hands soft as an added bonus.

At the end of the day, I settle on the couch with a glass of wine, hearing the soft ping of the jars sealing, one after another, as the contents cool. Another seasonal ritual enjoyed, another apple harvest completed, and another year of living in this beautiful and abundant place.

Post by Julia Conway on October 22nd, 2009